Winter 2018

From the Desk of Jon Gasperini

Starting out 2018 with a New Partner and Culture!

When you first fly into Osaka, Japan, you are struck by how large the city and especially the port is. Once on the ground you are not surprised to find that the city is very beautiful and the people are friendly and welcoming.

My reason for going to Japan was a recent invitation by Lami Corporation to visit their headquarters, meet their team and see their operation. I was welcomed with the hospitality and professionalism that you would expect from a first class company. After spending a day with their executive group, I was treated to a tour of the state-of-the-art manufacturing facilities. I met with the engineers and technicians who preside over the design and construction of their patented laminators. The quality controls and attention to detail were very evident, what you would expect from experts who have been manufacturing laminators for over 38 years. There was no doubt that these machines would fit perfectly with our high quality standards.

We also found time to stop in on some local customers to see the machines in action. One customer had two Auto Atlas-14T machines running non-stop. The newest machine was over five years old! Quite a testimonial and much better than words.

At the end I’m happy to say, we successfully wrapped up my visit with an exclusive distributorship agreement for Lami machines and film. We are now extremely excited to offer these laminators to our customers. They are a perfect compliment to our well established Vivid machines, fitting the user between Vivid’s standard hand-fed roll laminators and the more automated Matrix line.

They are coming! The world’s best automatic desktop laminators: the Revo Office and Auto Atlas-14T.

And stayed tuned for a new process called HOT-LAM-CUT!!

Jon

Labor Pain

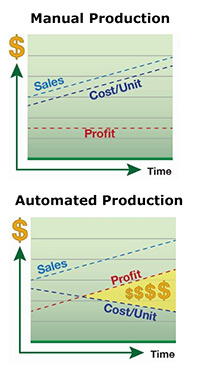

By buying a piece of equipment, you can add $3,000 per month

profit to your bottom line.

Sound unrealistic? It’s not really.

Sound unrealistic? It’s not really.

If you’re a manager or print shop owner, chances are you have experienced labor pain. That is – watching an entry level temp do an “easy” and somewhat repetitive task usually slowly with questionable quality results – think punching paper by hand or feeding a pouch laminator .

So what do you do?

You have a trusted employee, usually much higher paid, do the job. Or even worse, maybe you do it yourself because then at least you know it will be done correctly.

What’s the cost for this?

It’s not so easy to define in a simple ROI, because the opportunity costs are somewhat intangible. Could you make more money for your business by getting a new customer instead of “punching” paper? Could the manager be focused on getting other jobs out the door and invoiced instead of babysitting three temps? The answer is YES, but those facts get lost in labor pain haze.

In many cases a simple dollar based ROI justifies automation at any level, from your pouch laminator work to automatically processing high volumes of large wire-bound school work pads.

In many cases a simple dollar based ROI justifies automation at any level, from your pouch laminator work to automatically processing high volumes of large wire-bound school work pads.

When you eliminate labor pain, automation

is a slam dunk!

If you would like some help finding more profit by automating, contact us for a free consultation.

Machine of the Month

![]()

RENZ ECL 360 Electric Wire Closing Machine

No effort required with the ECL 360. Wire bind all your products quickly and easily.

- Max. binding edge: 14″

- Close diameters from 1/4″ – 1-1/2″

- No set up required

- Quick, easy diameter adjustment in seconds

- Automatic protection safety switch

- Parallel adjustment in seconds guarantees a perfect bind every time

- 250w motor

Take a look how easy it is to operate the ECL 360!

For more information on the ECL 360 contact Jon Gasperini.

Mike G.

Miami, FL

A . There are a few reasons your foil might not be making a good bond with your toner. The main variables that can affect this are heat, speed and pressure. In general not enough heat or too much speed can cause poor coverage or a “pinhole” effect that looks like it is pitted. When foiling over a laminated sheet, too much heat can actually “lift” the toner off the sheet causing a broken appearance in the foil or black toner showing through. Also paper stocks can play a role in how toner and foil bond- so make sure you test accordingly.

What Our Customers Are Saying!

“We are a trade bindery in East Hartford, Connecticut. Our mechanical binding has increased 60% over the last six months so I called in Jon and Alan from Databind in Enfield, Connecticut. We discussed our increasing Ring Wire needs and decided to purchase their Renz Autobind 500HS. Needless to say, it is everything they promised. This machine has been a huge time saver for us. The set-ups are fast and easy. The operation is flawless and the product looks perfect. Jon and Alan were tremendously helpful throughout the entire process.”

Steven Pensiero

President

STP Bindery Services, Inc.

East Hartford, CT

(860) 528-1430

Jon Gasperini

860.265.3222 Helping customers by:

Delivering Profitable Solutions for Your Business