Spring 2018

From the Desk of Jon Gasperini

So what to do with so much information to share?

That was the dilemma Renz was facing with so many new innovations and partnerships in process. How would they inform their distributors all around the world so they could share it with the global markets?

Then someone had the great idea to pull everyone together for an International Renz Seminar! Usually reserved for Drupa this gathering saw the most Renz distributors together in one place since 2004!

Well, it was SUPER!

True to their promise the young management has successfully embraced the digital world and put action to their words. There are too many exciting things coming out to properly inform our North American friends in one short newsletter.

But please stay tuned!

In the coming months you will see it all!

Jon

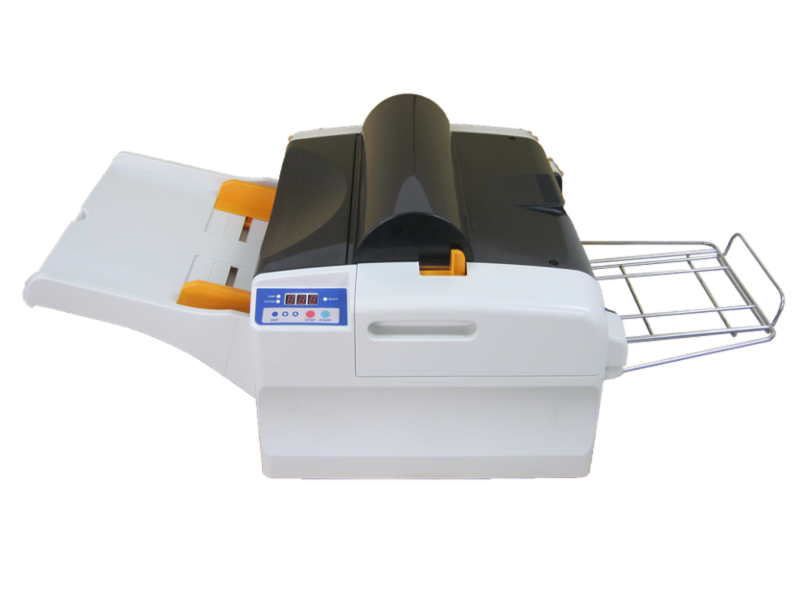

Now available in the U.S. and exclusively offered through DataBind!

Increase productivity with automatic feeding, laminating and cutting.

The Revo-Office automatic laminator will do it all with one touch of the start button – automatic feed, laminate and cut. With a compact design and simple operation, the Revo-Office laminator is perfect for the office or copy shop.

Film change is easy and fast with the patented two roll cassette. Just lift out and replace. And best of all the Revo-Office can process up to 240 sheets/hour automatically.

If you’re currently using a pouch laminator, tired of feeding each sheet by hand, and would like to save time and get a premium quality lamination, then the new Revo-Office laminator is for you!

Check out the video below that shows the new Revo-Office in action!

Revo-T14 includes

cabinet/stand

Fully automatic laminator for high productivity demands and a new process called HOT-LAM-CUT!

The Revo-T14 automatic laminator is the perfect solution for higher productivity demands.

Offering automatic feeding, laminating and cutting, the Revo-T14 will save labor costs and time.

With a compact design and small footprint, the Revo-T14 offers a two film roll system that’s easy to change – adding flexibility and quick change out for different film choices.

The Revo-T14 can process 5x faster than a desktop laminator and up to 420 sheets/hour vs.72 sheets/hour with a pouch laminator!

The Revo-T14 can process 5x faster than a desktop laminator and up to 420 sheets/hour vs.72 sheets/hour with a pouch laminator!

You can also create custom on-demand die cut materials using the new Revo-T14 combined with a Summa cutter!

The sample doorhanger “What Happened in Vegas” was a hit at a recent event and is just one sample of the new on-demand process! Ask about how you can open up new revenue streams with HOT-LAM-CUT.

Check out the video below that shows the new Revo-T14 in action!

For more information about the Revo-Office, Revo-T14 and how to HOT-LAM-CUT, contact Jon Gasperini.

Machine of the Month

Matrix Omni-Flow Automated Deep Pile Feeder

The Matrix Omni-Flow is a modular system that retrofits to all Vivid Matrix Pneumatic and Duplex Laminating Systems.

Now you can save time and labor by automating your Matrix lamination feeding process. The Omni-Flow is quick and easy to install, set-up and operate.

- Load up to a 7-inch pile or 700 sheets (170 lb. paper)

- Max. sheet width: 15 inches

- Max. sheet length: up to 36 inches

- Full color digital touch screen

- Ideal for short to medium lamination runs

- Change between paper stock in seconds

Watch the Matrix Omni-Flow in action!

For more information on the Matrix Omni-Flow contact Jon Gasperini.

Thank you ADG!

A big thank you to the American Dealer Group for inviting us to their Annual Spring Meeting where we presented what’s new with Renz and our partners, Vivid, Stago and Lami. It was a well-attended event at a first-rate venue in Tucson, Arizona.

ADG members are seasoned professionals with a long history of supplying solutions for the prepress, printing and print-finishing industries. The group has adapted well to the ongoing changes in digital printing and our industry and are an informed and knowledgeable resource for all aspects of printing.

You can learn more about the group at www.americandealergroup.com.

Don H.

Austin, TX

A . This is a complex question with so many variables, but the quick answer is you need to find out what film works best on your specific machine and create a chart so you or a new operator can go back and reference it.

Many films will have a temperature recommendation, but that is usually the temperature the adhesive will activate at and not the temperature you should laminate at.

Here’s a best practice to follow for temperature settings:

1. Run hot enough to make sure the adhesive on the film is “wetting out” or has a tacky feel. Then run slow to start so the adhesive looks wet and shinny, if you run too fast it will have a cloudy look.

2. Next test sheets to make sure the bond is good, take the laminated sheet and cut a shallow X with a razor knife, try and cut only into the film and not the stock then try to peel off the film. On offset or ink jet prints you should be pulling up paper fibers, on digital print especially heavy dark coverage you won’t be pulling up fibers but should be pulling the toner up and it should take some effort to pull up.

3. I recommend writing the settings on a sheet before it goes through the laminator, that way if you get a good result you have a record of it, and like wise you will know what doesn’t work and will have a record of that. Record your good results into a spread sheet so you have a quick reference guide.

Have a question? Just send us an email to: asktheexpert.com

What Our Customers Are Saying!

“We already loved our Matrix, and our laminating and foiling business had been steadily growing over the year since we got the Matrix, adding the Omni-Flow feeder was like getting a complete new system and has increased our confidence in taking on larger jobs. Our comfort level was runs of 100-500 with the occasional 1000 sheets, since getting the feeder we have comfortably taken on 5000 sheet runs.”

“We already loved our Matrix, and our laminating and foiling business had been steadily growing over the year since we got the Matrix, adding the Omni-Flow feeder was like getting a complete new system and has increased our confidence in taking on larger jobs. Our comfort level was runs of 100-500 with the occasional 1000 sheets, since getting the feeder we have comfortably taken on 5000 sheet runs.”Jon Gasperini

860.265.3222 Helping customers by:

Delivering Profitable Solutions for Your Business